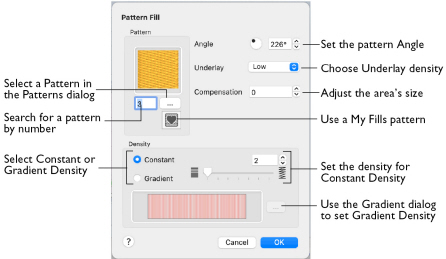

Use the Pattern Fill dialog to set the properties on a pattern fill area.

Pattern

Choose a fill pattern in the Pattern dialog.

Use the Options tab to see and change the settings for fill angle, underlay and compensation.

Angle

The angle of the fill pattern, as shown by the rotational slider and numbers box. The thread is at a right angle to the fill pattern. You can set the Angle from 0 to 359 degrees.

Note: The fill angle also affects the orientation of a gradient fill.

|

|

The example shows pattern number 56 with the fill angle set to 45, 90 and 180 degrees.

|

Underlay

Underlay is a low density fill that is perpendicular to the stitches of the actual fill area. It is useful for stabilizing large fill areas.

Note: Underlay stitches are not generated for areas using gradient density. However it can be selected, as you may change the area to constant density. Underlay is only generated when stitches are created.

-

Choose None, Low, Medium or High density underlay from the pop-up menu.

Compensation

Compensation is used to make an area 'bolder' by increasing its relative size. The higher the number, the bolder the area appears. The initial setting is 0.

-

Click the arrows to set Compensation from 0 to 20, or enter a value in the numbers box.

Density

Constant density creates a uniform fill at the chosen density. Gradient density creates a fill with varying density or color.

-

Select between Constant and Gradient density.

Setting Constant Density

The lower the number, the closer together the stitches and the more stitches are produced. You can set Density from 2 to 40.

-

Select Constant, then use the slider or the numbers box to set the Density.

Setting Gradient Density

-

Select Gradient, then click the ellipsis button (3 dots) to open the Gradient dialog. See Gradient.